"HOW DID IT BREAK AND WHY - 2018 Edition"

I am a Materials Science & Engineering Professor and this time of the year (November) it is time to introduce our freshmen to the discipline with a small project that I call "How did it break and why". First stop at the stereo microscope. Of course it is a....Waterman nib.

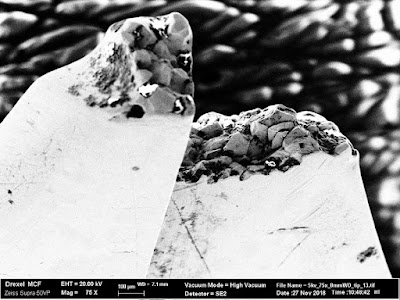

Detailed examination of one the cracks reveals that it is actually a stress corrosion crack. Stress corrosion is when a material breaks under the combined action of stress (repeated stress here, thus fatigue) and corrosion. The students asked me how come gold corrodes. Actually it does [1] especially as the purity decreases (lower K). Then the asked me who did I infer that there was corrosion. The answer of this was a little more elaborate. The shape of the top crack gives it away. Non only there is a crack but there is material missing on the surface of the nib and the sides of the crack. Moreover the surface of that area is faceted and it indicates that the material was removed along the grain boundaries. Then they asked me what are grains (remember - they are freshmen). So I explained to them that metals are crystalline materials (i.e. their atoms are arranged in a lattice) but they are most of the times built from many, many crystals that are next to each other with different orientations (what we see sometimes on the surface of galvanized steel). The boundaries between the grains are more susceptible to corrosion - this is a sophomore year detail - I told them In fact there were much more spectacular signs of stress corrosion at the broken tip, which I will show it to you in the next set of SEM photographs. Enjoy these for the time being

In fact there were much more spectacular signs of stress corrosion at the broken tip, which I will show it to you in the next set of SEM photographs. Enjoy these for the time being

To complete the story, the infamous Waterman nib that ended up under our electron microscope has a second interesting story. The tip is missing from both tines and one of the tines was broken around 0.5-0.7mm behind the tip. High magnifications show a clear intergranular fracture which is clear indication of corrosion stress cracking. Interesting are: (a) the area that show wear lines perhaps from the usage of the nib "sans iridium", and the second big trasnaverse crack below the main fracture on the right tine. Bad composition? Highly corrosive ink? Both? Possible. We will look futher into the details of the microstructure in an upper level class on "Case Studies in Materials"... I am not sure if the students enjoyed as much as I did. I was as giddy as a six year old with this project

I am a Materials Science & Engineering Professor and this time of the year (November) it is time to introduce our freshmen to the discipline with a small project that I call "How did it break and why". First stop at the stereo microscope. Of course it is a....Waterman nib.

Detailed examination of one the cracks reveals that it is actually a stress corrosion crack. Stress corrosion is when a material breaks under the combined action of stress (repeated stress here, thus fatigue) and corrosion. The students asked me how come gold corrodes. Actually it does [1] especially as the purity decreases (lower K). Then the asked me who did I infer that there was corrosion. The answer of this was a little more elaborate. The shape of the top crack gives it away. Non only there is a crack but there is material missing on the surface of the nib and the sides of the crack. Moreover the surface of that area is faceted and it indicates that the material was removed along the grain boundaries. Then they asked me what are grains (remember - they are freshmen). So I explained to them that metals are crystalline materials (i.e. their atoms are arranged in a lattice) but they are most of the times built from many, many crystals that are next to each other with different orientations (what we see sometimes on the surface of galvanized steel). The boundaries between the grains are more susceptible to corrosion - this is a sophomore year detail - I told them

[1] Dugmore, J. M., & DesForges, C. D. (1979). Stress corrosion in gold alloys. Gold Bulletin, 12(4), 140-144. https://core.ac.uk/download/pdf/81824208.pdf

1 comment:

Thanks for sharing your research and thoughts. I came across this blog while researching into iridium tipping for fountain pens. I hope you are still updating it as there is so much to learn here. Best regards - Lily of Grail Pens

Post a Comment